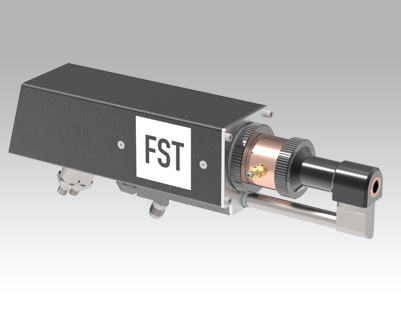

The JP-5000 HVOF gun is designed for the liquid-fuel HVOF spray process and can be considered as the benchmark for HVOF guns. Robust, long-lasting components are used throughout, ensuring long spray runs and low maintenance requirements.

The JP-5000 HVOF gun is designed for the liquid-fuel HVOF spray process and can be considered as the benchmark for HVOF guns. Robust, long-lasting components are used throughout, ensuring long spray runs and low maintenance requirements.

The JP-5000 liquid-fuel HVOF gun is a proven design using economical kerosene fuel to generate high quality, dense, wear resistance and/or corrosion-resistant coatings. Coatings can be applied very thick and exhibit favourable compressive stresses that increase bond strength and coating performance. The JP-5000 design is simple, rugged, featuring durable, long service life components that can withstand the harshest industrial spray environments, reliably and repeatedly.

The JP-5000 is designed for liquid-fuel (kerosene) and oxygen operation. Fuel and oxygen are fed into the gun, atomized by the coaxial stabilizer and ignited in the combustion chamber, resulting in a supersonic flame. Spray powder from the powder feeder is fed radially into the supersonic flame through two powder ports positioned directly after the combustion chamber. The spray stream is accelerated through a converging/diverging nozzle several times the speed of sound. The spray particles are heated to a molten or semi-molten state and propelled at high velocity, impacting the coating surface in a plastic state.

Several barrel lengths (4, 6 and 8 in) are available to optimize the dwell time of the spray particles in the jet stream while keeping the dwell time of the particle to a minimum.

Liquid fuel HVOF offers certain advantages over gas fuel processes, such as the easy availability and handling of fuel, and higher energy density associated with these fuels. The increased quantity of heat available results in denser coatings with higher bond strengths.

Features & benefits JP-5000 HVOF Spray Gun

- Coating exhibit excellent wear resistance.

- Superior microhardness compared to other thermal spray technologies

- Very high bond strengths, typically exceeding 80 MPa (10000 psi)

- High-density coatings with minimal porosity

- Low impurities and oxides levels

- Compressive stresses in the coating.

- Thick coatings, up to or exceeding 6 mm (0.25 inch) are possible

- Smooth “as-sprayed” surface finishes

- Low-cost process using liquid fuel (kerosene)

- Dual-port, radially fed powder injection

- Simple design resulting in low and easy maintenance.

- Different barrel lengths available for specific spray materials/coating results

- Highly polished barrel ID’s minimize build-up of material in the barrel.

- Safe and reliable remote ignition design.

- Machine-mount for use with robots and traverses systems

![]() JP-5000 HVOF Spray Gun spare parts

JP-5000 HVOF Spray Gun spare parts